Our Work Gallery

We guarantee customer satisfaction. In the unlikely situation that you are not happy with our job we will re-attend and rectify the item requested. If this cannot be achieved to your satisfaction we will refund you the value of this work.

Mould Remediation on Two level Commercial building and all contents

Situation

This building was Queensland State Office of a large Multi-National manufacturer and retailer. Due to air conditioner system, the particle timber floor including a mezzanine above the 1st level developed conditions favourable for mould germination. Commercial Property Company sought services from an International Risk Management organisation with expertise in mould to develop a contract of works and requirements to be adopted for handling mould contaminated material/remediation employing methods in accordance with S520 IICRC Professional mould remediation (building was 2,747 cubic meters).

Moisture Control Services (MCS) in close association with a local Building Firm developed a scope of works which included removal/storage of all contents, disposal of all ceiling tiles, means of protecting carpet on ground level, removal/replacement of floors and mould remediation while at the same time allowing the continuous operation of the State computer server room where controlled air temperature was required.

Complexities

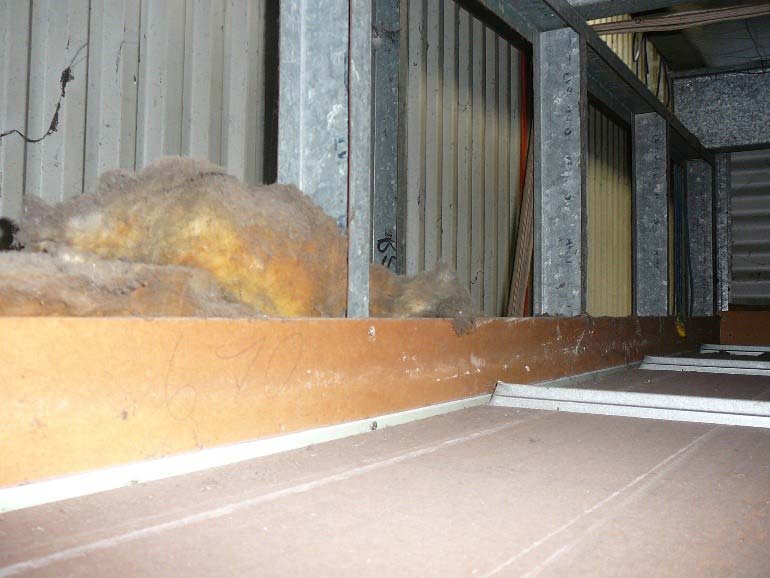

Contract of works stated negative air pressure was needed to prevent cross contamination however upon detailed inspection it revealed that the upper walls on one end of both floors were left open (end of building is actually inside the warehouse but a gap exists between warehouse wall to that of the office).

External warehouse wall and gap between the two structures – End of office wall inside ceiling cavity – Ceiling tiles that will be disposed

Other issues existed that needed to be considered included:-

- Remediation of computer server room while maintaining temperature controlled environment;

- Stairwell which was 6.6 metres high from ground to ceiling of the 1st level;

- Compactus full of records – solution was to wrap each sliding shelf in plastic before commencement of work.

- Effective means to treat ceiling cavity area 3.3 metres high including wires and air conditioning system.

Containment walls and staging

Total containment walls erected over this project measured 65 metreins approximately.

Work was staged so that after each section was remediated by MCS, the Builder could commence installing ceiling tiles and new carpet (where applicable) which allowed for the project to be completed on time.

Remediation

MCS investigated best means to reach and treat ceiling cavity area and decided upon using a mini Zippy-Scaff. This allowed MCS to treat approximately 1.5 to 2sqm area at a time depending upon air conditioning system elements above. Solutions used for mould cleaning were attached at each end of the zippy-scaff with HEPA vacuum in the corner. This allowed MCS to complete entire section at once as per work contract. MCS also extended length of the HEPA vacuum hose to assist in reaching the above area which was wide and long metal ducting.

Work contract included treating ceiling cavity area however when the mezzanine floor was removed, debris fell through onto the first level and the same occurred to the ground level when removing the floor above. Consequently, at completion of cavities all walls, windows and floors needed to be treated as well.

In order to cater for the computer server room, it was agreed for MCS to remove the ceiling tiles. In order to control temperature, half the ceiling tiles were removed, the cavity on this side of the room was treated and then plastic was looped over the suspended ceiling tile racks (refer photos below). The other side of the tiles were then removed, treated and then plastic was looped over the suspended ceiling tile racks for the balance of the room. This allowed the area to remain within controlled temperature range during and after such works until the ceiling tiles were replaced which was approximately 1 week later. For the stairwell, trestles and double planks with clamp were used to reach this area where the bottom of the trestle was chocked so it could not move during such work.

Timber Floor Drying

When Builder removed the particle timber floor, it had to be cut out around existing fixed walls where small section of the original board was left in place. The Risk Manager handling this job advised that two sections on the eastern side and majority on the western side has retained moisture and needs to be dried. For the Eastern side sections, heat mats were used and for the western side due to the wide area. Dehumidification was used at first and heat mats on the last sections. MCS took moisture readings and forwarded these to the Risk Manager until it was sufficiently dried.

Contents

It was considered wise to treat all contents that was being stored in open area of large warehouse and for all fabric chairs to be disposed. This as well as timber floor drying were variations to the quoted project.

This job included all forms of office furniture (over 160 items) which were HEPA vacuumed and wiped with mould cleaning solution. Clear carpet protector mats were treated with mould cleaning solution and allowed to dry naturally. Only one piece of furniture was beyond restoration due to swelling of the lower chipboard surface.

Clearance Testing

The Risk Manager attended site several times during this project to take combination of surface and air samples to ensure the conditions were back to normal mould ecology before various containment walls were removed. MCS in all cases achieved the desired outcome and 100% of all surface samples taken endorsed effective treatment adopted by MCS.